Advanced Microscopy

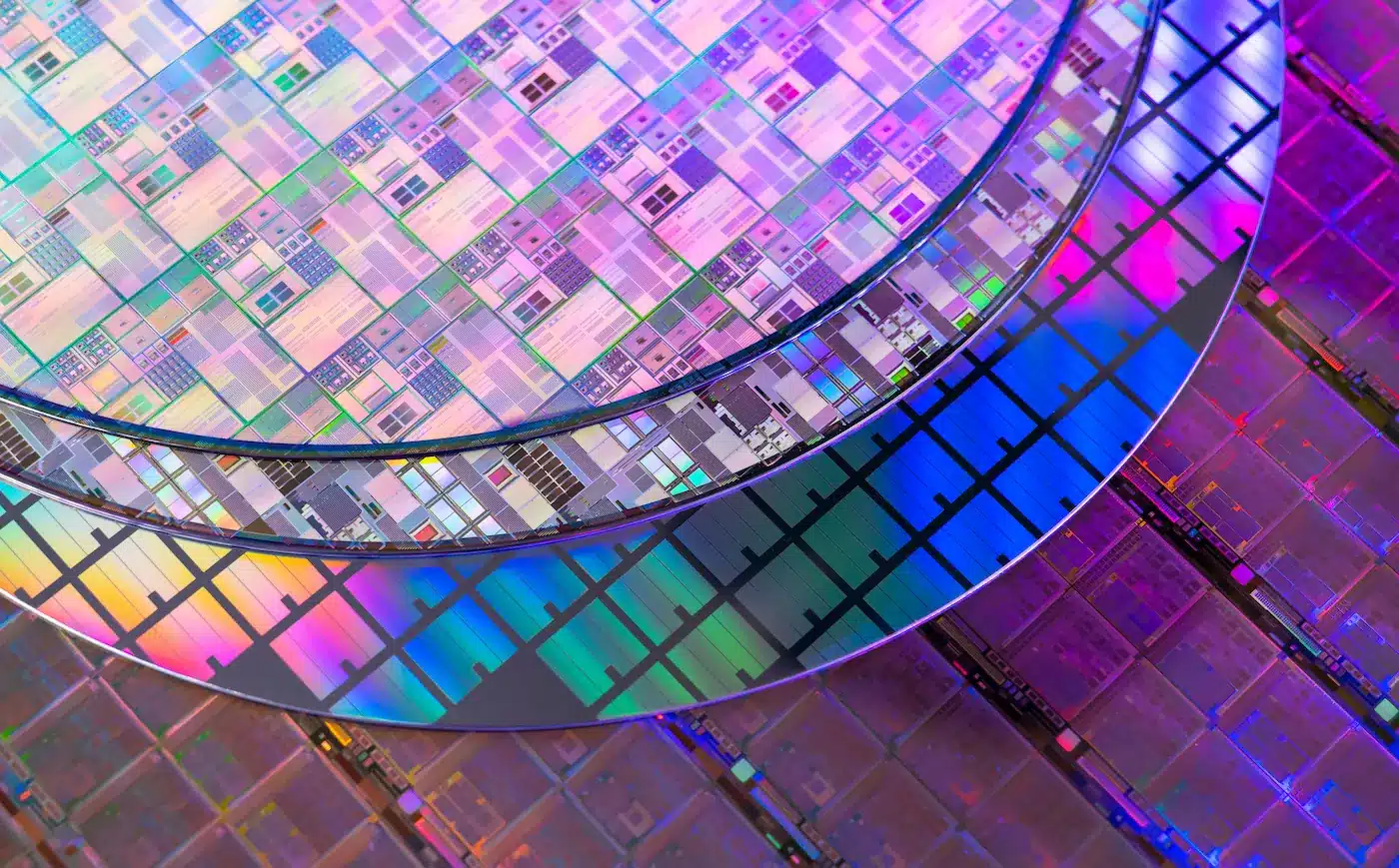

Transmission Electron Microscope

As one of the first operators in Western Canada, nanoFAB provides training and access to JEOL JEM-ARM200CF Transmission Electron Microscope

- 200, 80, and 60 kV acceleration voltage

- <0.1 nm resolution (HAADF STEM)

- Large-angle SDD-EDX detector

- In-situ heating and electrochemical holders

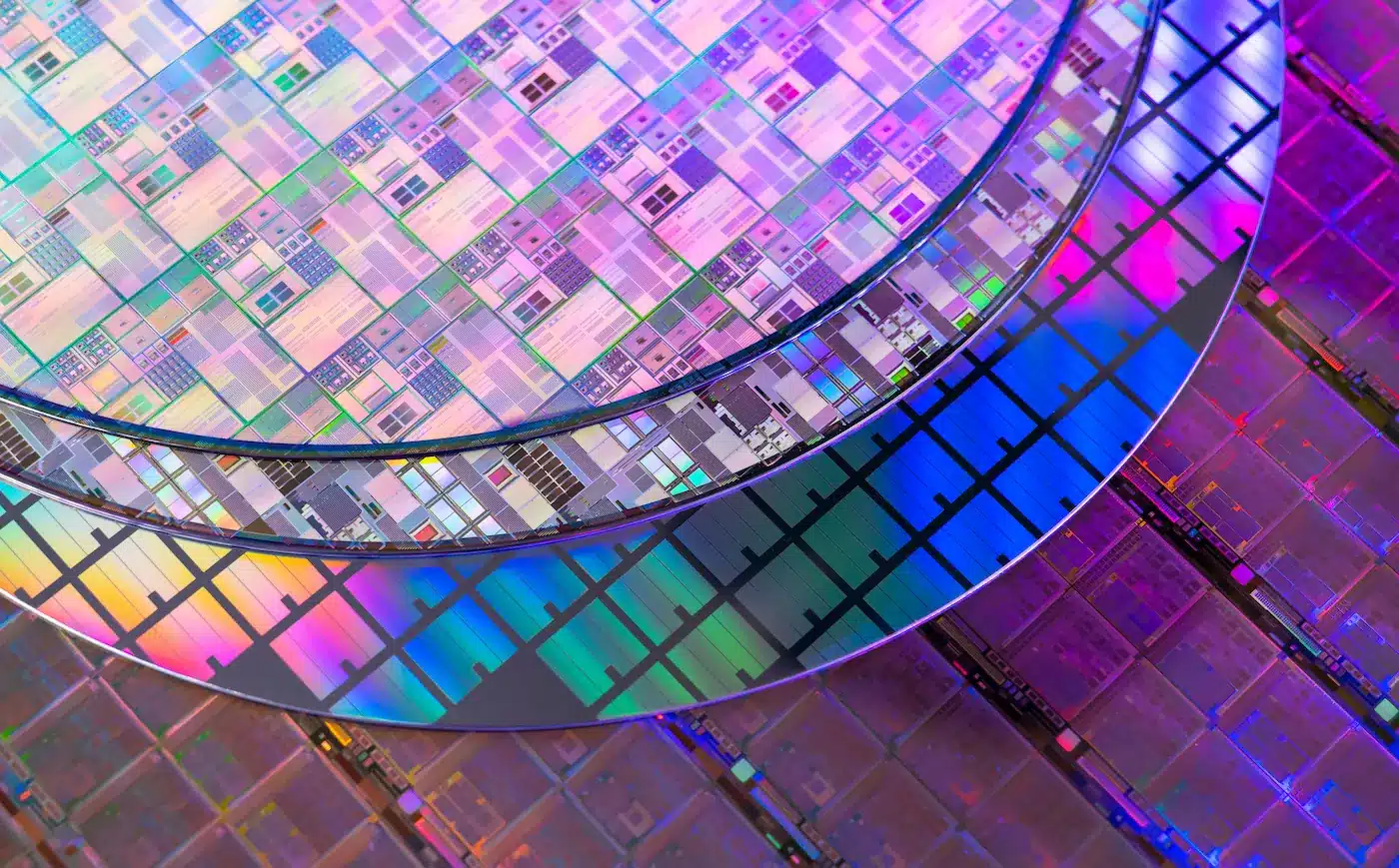

Focused Ion Beam (FIB)

ThermoFisher Helios Hydra Plasma FIB/SEM dual-beam system, equipped with multiple ion species, micromanipulator, gas injection system and fast EDX detector, is widely utilized for ion-beam patterning, micro-sample manipulation/preparation and 3D characterization

- Multiple Ion species: Xe, Ar, O and N

- Ultra high resolution FESEM: 0.6 nm

- Analytical detectors: STEM, BSD, EDX

- Gas injection system (GIS): C, Pt and W

- TEM sample preparation

- FIB/SEM tomography

- Transfer shuttle for air-sensitive materials

- Direct ion beam patterning

(Field-Emission) Scanning Electron Microscope (SEM)

The nanoFAB houses 3 SEMs (2 FESEMs and 1 thermal emission SEM), supporting different levels of SEM analysis needs, including undergraduate and graduate courses, entry-level inspection, and advanced analytical characterization

Zeiss Sigma FESEM

- Schottky field-emission source

- Excellent low-voltage imaging

- EDX and EBSD detectors

Hitachi S4800 FESEM

- Cold field-emission source

- STEM and EDX detectors

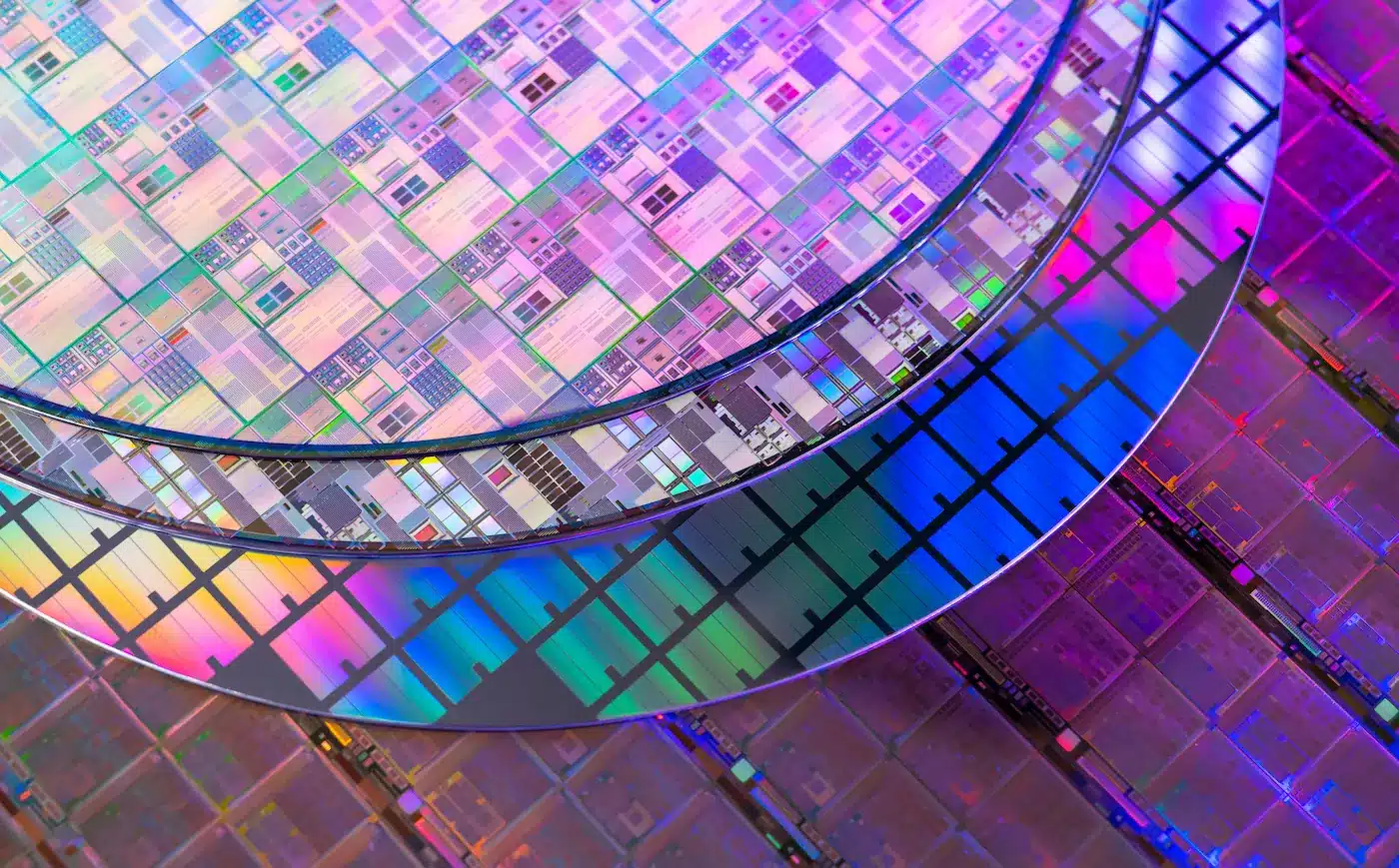

X-Ray Microscopy / nanoCT

Zeiss Xradia Versa 620 XRM provides high throughput, non-destructive, high resolution 3D/4D analysis of materials that are not limited to vacuum compatibility.

- Non-destructive high resolution 3D X-Ray imaging: better than 500 nm

- High power (25 W) X-Ray source with energy range of 30 – 160 kV

- Integrated in-situ thermal/mechanical testing stage (Deben)