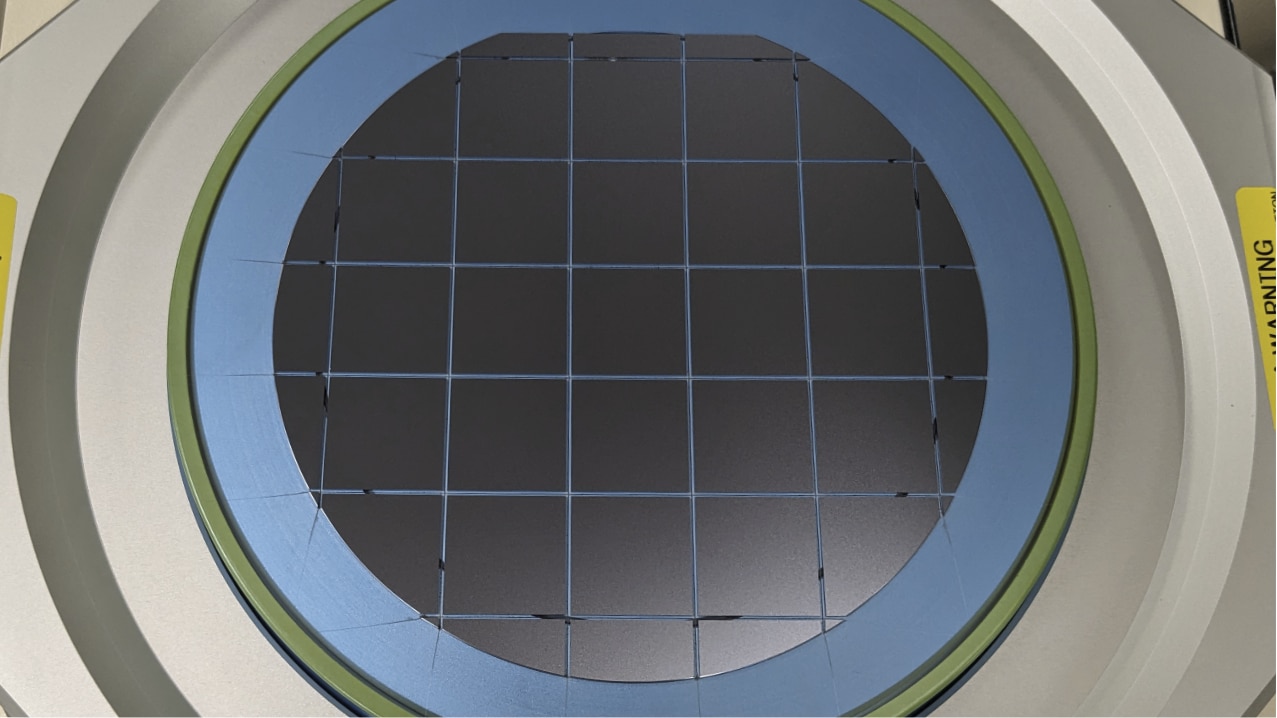

New Die Matrix Expander Available

In semiconductor processing, packaging is a critical step in finishing a final product. After completing the dicing process to singulate dies from a larger substrate, the cut dies generally remain affixed to dicing tape. It can be difficult to manually remove the dies without scratching or rubbing against one another, causing chipping or other damage. A die expander allows for the tape to be stretched on expander rings, separating the dies for easier removal or shipping.

We are happy to announce the addition of a Hugle Model-1810 Die Matrix Expander to the nanoFAB's tool lineup. This expander is capable of accommodating diced specimens up to 150 mm in diameter. It is equipped with a heated chuck, allowing for easier separation of the dies without delamination from the tape, as well as a preheat timer, which helps with process repeatability. The stage expansion distance is adjustable, allowing for customized spacing between the dies. The system also includes an automated cutter tape separation system for ease of use. Previously, without the use of this tool, users in our facility needed to mount diced 150 mm wafers onto the expander ring by hand, a task that often required two people to do!

We hope that the addition of this new system in our toolset will facilitate the final processing and packaging of the many devices fabricated in our open-access facility. Please submit an equipment training request via LMACS if you wish to get trained on the die expander. For more information, please contact Breanna Cherkawski.

Please see below for some videos of the tool in action: