Spin Mill with Plasma FIB

A new approach – Spin Mill, for large-area planar milling with ion beams is now available on the Thermo Fisher Helios Hydra Plasma FIB/SEM for accessing and investigating large areas (up to 1 mm).

The Spin Mill method offers alternative planar sample preparation, expanding the PFIB-SEM application beyond the conventional cross-section technique and Broad Ion Beam (BIB) milling. In combination with the flexibility of multi-ion milling, Spin Mill provides site-specific large area processes for various types of materials, which enables new characterization capabilities previously considered challenging.

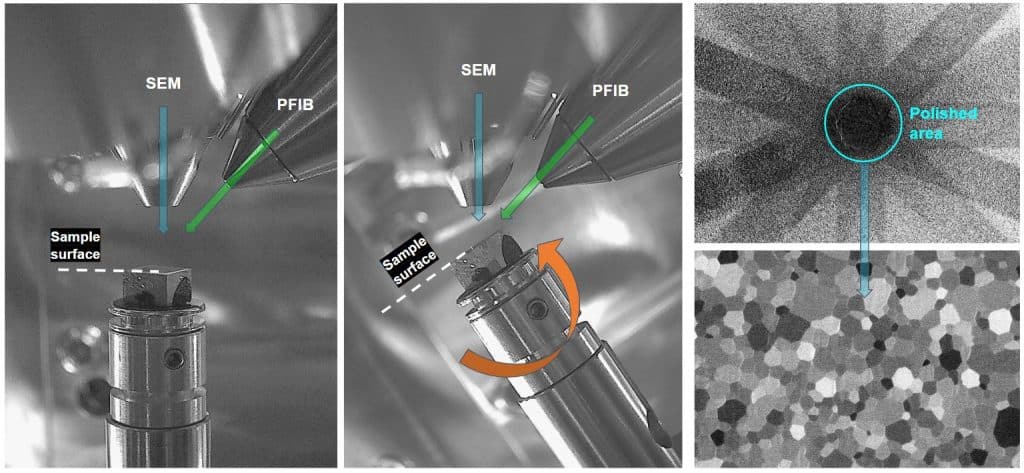

Spin Mill setup in Hydra PFIB

In the Spin Mill setup, the sample is mounted horizontally on the stage. The stage is tilted negatively, so that the PFIB beam mills the sample surface at a nearly glancing angle (typically between 1 and 5 degrees). The stage is periodically rotated through a full rotation of 360 degrees, which results in uniform planar polishing.

EBSD applications

While the Spin Mill application offers new capabilities in a wide range of materials characterization, several groups have benefited from it for their EBSD analysis.

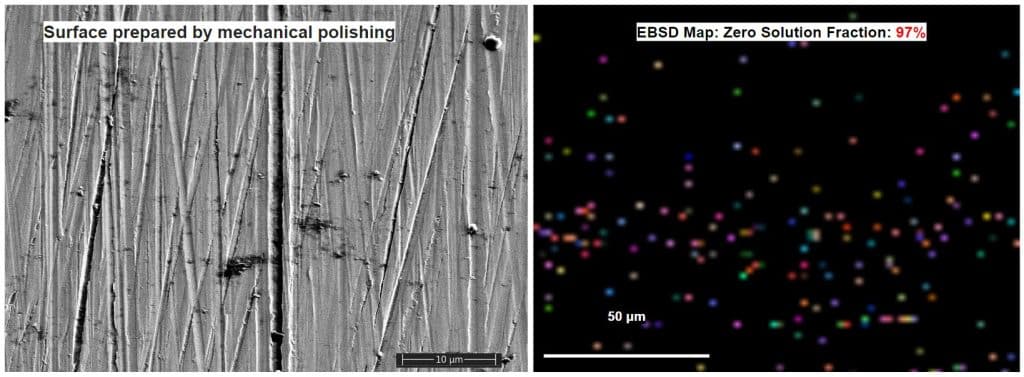

- Sample: Rail Steel

- Sample Courtesy: Stephen Okocha, Drs. Ben Jar and Michael Hendry, Mechanical Engineering Department, Civil and Environmental Engineering Department, Faculty of Engineering, University of Alberta

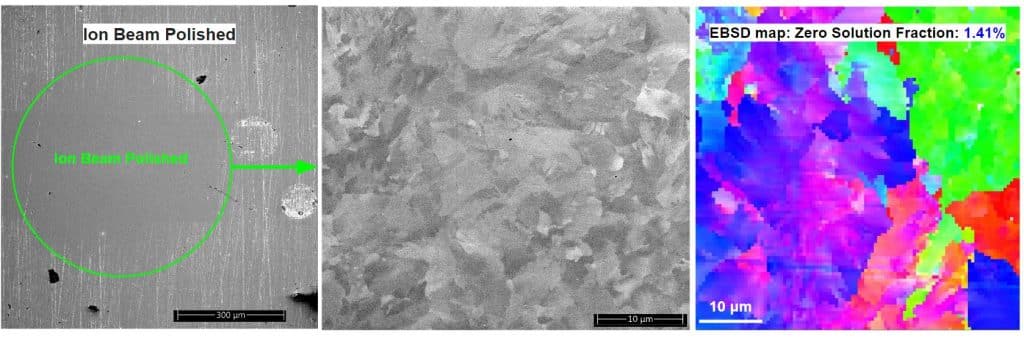

- Xe ion beam was used as a general polishing of a rough surface after mechanical polishing. Hit rate was increased from 3% to 98.6% after ion beam polishing.

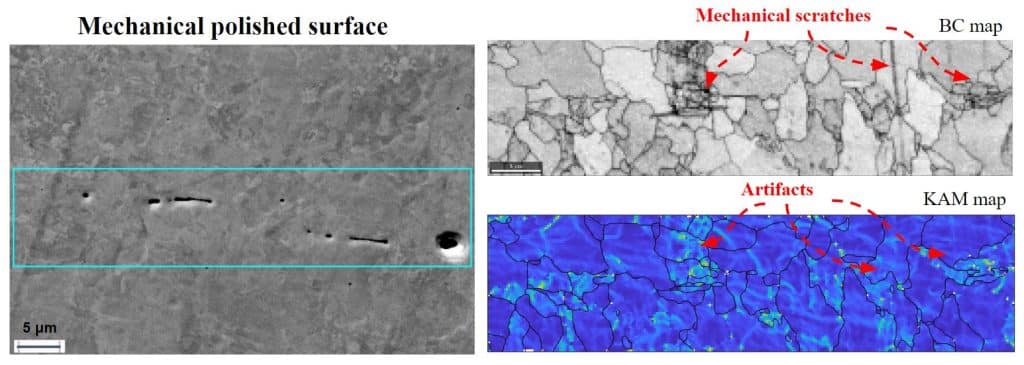

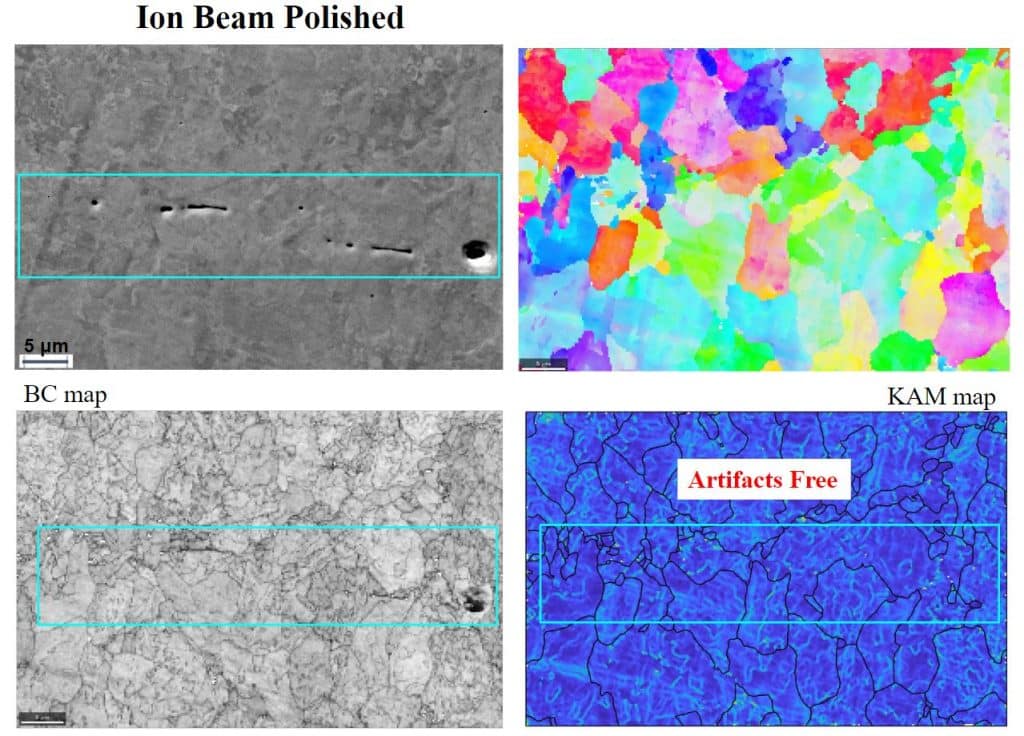

- Sample: Steam pipe welds in power and heat supply line for mining of natural resources

- Sample Courtesy: Yajing Wang, Dr. Leijun Li, Chemical and Materials Engineering Department, Faculty of Engineering, University of Alberta

- Shallow mechanical scratches and small porosity effects on EBSD are removed by Xe ion beam polishing.

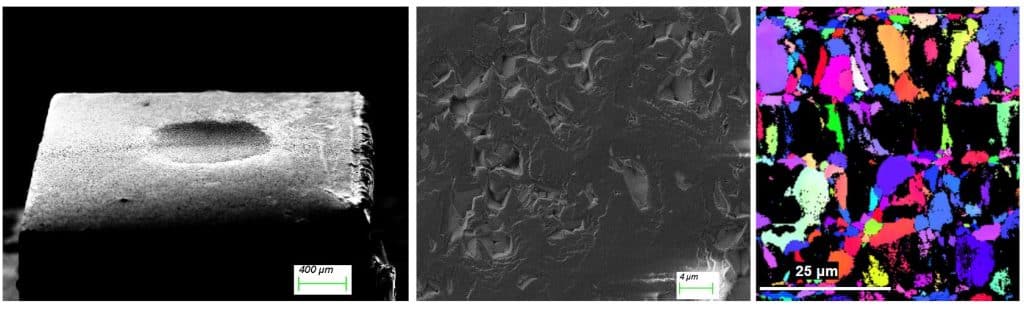

- Sample: 3D printed Alumina for structural applications, including protection, aerospace coating&components and filtration systems.

- Sample Courtesy: Cass (Haoyang) Li, Dr. James Hogan, Mechanical Engineering Department, Faculty of Engineering, University of Alberta

- The Spin Mill method effectively polishes porous structures due to glancing incident angle to produce smooth surface for meaningful EBSD analysis.

If you need to process your samples by ion beam spin mill, please submit a “sample” request with sample details on LMACS. If you have any questions, please feel free to contact Peng Li (Peng.Li@ualberta.ca) – the Characterization Group Manager.